Huaian Ku Yu Machinery Co., Ltd.

Telephone:0517-83717380

Phone:18952335311

Zip code:23005

Fax:0517-83712629

mailbox:kysunfang @163.com

URL:www.hakyjx.com

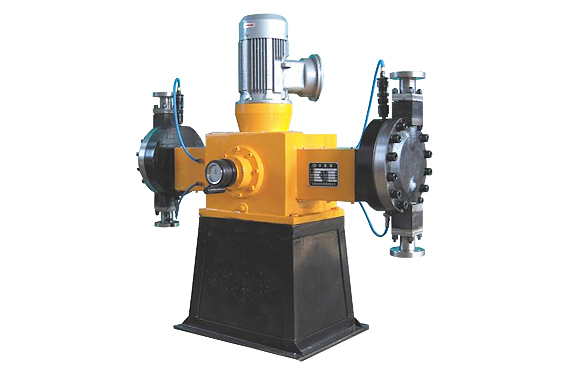

The application of pump products in life is very wide. The pump products have metering pumps, hydraulic pumps, centrifugal pumps, pumps and so on. Popularly speaking, the pump is the machinery that controls the flow. Different pumps have different characteristics. For example, the metering pump can precisely control the amount of fluid, which can mainly be used for the material proportioning of industrial production. So, how does this kind of product be repaired? Diaphragm meter below

Pump manufacturers to explain what the pump needs to master the maintenance skills.

1. How to dismantle the old diaphragm

Move the hydraulic end by loosening the 4 pump head screws. Rotate the stroke length to 0% and grab the hydraulic end, then slide out from the screw hole, then the screws do not contact them, but also hold the back and diaphragm. Then the component is rotated counterclockwise, with slightly resistance, and the diaphragm will loose from the electromagnetic axis. If the diaphragm is not loose yet, use some lubrication on the contact surface of the diaphragm and the electromagnetic shaft.

Oil. After a few minutes, use a small plastic hammer to gently tap the diaphragm. Then it is done again according to the above description.

Two. How to replace the diaphragm of the metering pump

1. remove the 4 screws of the fixed pump head. The screw position is on the back of the metering pump.

2. after the pump head is loose, before taking down the head of the pump, adjust the length of the stroke to the 0% position. It can ensure that the electromagnetic shaft has enough pressure to keep its connection stable so that the diaphragm can be swirled down.

3. pull out the hydraulic end to disconnect the screw from the socket. Grab the liquid end and rotate counterclockwise. A little resistance can spin off the diaphragm.

4. once the diaphragm is taken off, check the safety diaphragm of the metering pump to ensure that it is intact, without any damage. Install a new diaphragm and rotate the back and diaphragm clockwise until tight. Adjust the back plate so that the drain hole is located at the bottom of the pump.

5. after the diaphragm is installed, and the drain hole of the back plate is placed in the vertical position, the pump head is installed. Ensure that the suction valve is aligned with the drain hole, and the screw of the hydraulic end is aligned with the corresponding 4 holes.

6. rotate to the 100% position of the stroke length. This allows the complete set of parts to be rotated to the bottom of the back plate leakage hole and the bottom end of the pump. Adjust the hydraulic end and diaphragm to the appropriate position during the operation of the pump.

7. when the hydraulic end is adjusted with the back plate position, the 4 bolts are tightened in the diagonal way until it is suitable. The work should be carried out evenly.

Three. When using the self-priming method to measure the hydrogen peroxide, the gas hole is produced in the system. How to solve this problem?

The metering pump is installed from the exhaust pump head, and the self irrigation fluid is used. Keep the sucking pipe as short as possible.

Four. Do not measure the liquid after installation and operation of the metering pump?

1. is the drain pipe installed and the drain valve closed? The discharge valve should be opened at the stage of metering pump injection. Note: not all metering pumps have discharge valves.

2. there may be a gas leakage at the suction end of the metering pump. The suction side connector of the hydraulic end may lack the looseness of the O type or the suction valve.

3. valve metering pump may be blocked, liquid can not be measured.

4. the stroke length of the metering pump is not set.

5. of the chemicals that are measured may crystallize at the end of the hydraulic force, causing the unidirectional valve ball and seat to not work properly.

Five, when we use flow monitoring to measure a high viscosity medium, we have received the flow fault indication signal in the process of liquid delivery. How can we solve this problem?

For the reaction time, the duration of the pulse may not be long enough. Compared with the standard pulse width 80msec, the pulse width expansion of the flow monitor can be activated to increase the pulse width to 300msec. Activate the smart switch, remove the cover fixed circuit board, remove the jumper X-1. This activates the extension function and allows more time before the failure indication.

Six. How to prevent the burning of the stroke positioning motor?

When adjusting the stroke position, ensure that the motor of the metering pump is always running. If the pump motor is not running, the stroke length adjustment lever will resist the tension of the compression spring, which will lead to the premature damage of the stroke positioning motor.

Huaian Ku Yu Machinery Co., Ltd.

Address: Fuzhou Road 12, Huaian economic and Technological Development Zone

URL:www.hakyjx.com