Huaian Ku Yu Machinery Co., Ltd.

Telephone:0517-83717380

Phone:18952335311

Zip code:23005

Fax:0517-83712629

mailbox:kysunfang @163.com

URL:www.hakyjx.com

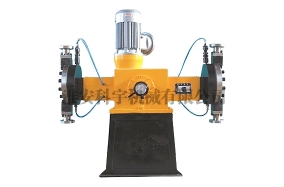

Xiaobian has talked with you about the common problems and solutions in the process of measuring pumps. But the most important thing we can't ignore is cleaning and maintenance of metering pumps at regular intervals. Underneath Huaian, the small editor of the drug metering pump manufacturer continues to introduce what steps should be taken to remove the cleaning when cleaning:

(1) first hit water for about 10 minutes, then playing about 5 minutes later, determine the canal water discharge, began the demolition action, in order to reduce the risk.

(2) shut down the power of the diaphragm metering pump and remove all the valves. When removing, we must be careful of the residual agents and moisture, so as to avoid damaging or splashing into the power supply and other related equipment, and cause damage.

(3) rinse the valve and the parts in the valve with clean water.

(4) check whether the parts have defects, deformation, crack and other conditions, if there is a replacement.

(5) all valve parts are installed in the original sample.

(6) test the water for 5 minutes (if there is crystallization, use the crystalline diluent for about 10 minutes, and then replace it with clear water for about 5 minutes). In the maintenance assembly and disassembly, the metering pump should pay attention to a certain order, especially the liquid cylinder components and the transmission box.

Disassembly of the parts of the hydraulic cylinder:

1. First, remove the pipe and accessories which are connected with the one-way valve.

2, remove the pump head, spin out the diaphragm (at this time best communicate with the manufacturer), and then the cylinder head connection from the drive box down;

3, according to the following order of all demolition tappet assembly parts: remove the A. spring seat son; turn out a spring seat, a spring, such as grinding tappet; composite bearing replacement removed, replaced with the same type. B. remove the suction valve (flange); take down the valve sleeve, the limit plate, the seat, the valve ball.

Disassembly of the transmission box:

1, let out the lubricating oil in the box body.

2, remove the motor, a motor seat, pull coupling, bearing plate, Jeanne worm assembly.

3, remove the regulator assembly, from the assembly and adjustment handwheel adjusting top rod, etc..

4. The two ends cover of the spindle can be unloaded, and the worm wheel, eccentric wheel and spindle can be removed from the box.

The above is the dismounting and cleaning steps, when assembling it by reverse demolition. At this time, it is important to pay attention to the inspection of the assembly gap after the assembly parts, and if the assembly is complete, there is no clamping phenomenon when the assembly is complete.

Be careful:

1, when assembling the slide sleeve adjuster seat, the adjusting top rod must be screwed to the dead point, and the adjusting hand wheel can be screwed to the scale of 20, and the hand wheel is fine-tuning to make the adjusting bar match the chute with the chute.

2, adjust the packing of the nut to tighten the tightness of the nut, and turn the coupling to turn.

Huaian Ku Yu Machinery Co., Ltd.

Address: Fuzhou Road 12, Huaian economic and Technological Development Zone

URL:www.hakyjx.com