Huaian Ku Yu Machinery Co., Ltd.

Telephone:0517-83717380

Phone:18952335311

Zip code:23005

Fax:0517-83712629

mailbox:kysunfang @163.com

URL:www.hakyjx.com

The drug metering pump adopts the sensing signal to control the working process of the drug pump. The control method is required to use the pH meter, the conductivity meter and other monitoring instruments and corresponding sensors. First of all, according to the operation need to set control parameters (pH) or conductance value limit value, if the system in the process of running the following dosing system in which to work: if the pH value is less than or greater than set value. The low pH value indicates that the acid is too acidic and the system is prone to corrosion. The pH value is on the high side, indicating the alkaline is too strong, the system has the tendency of scaling.

When testing instrument will be the feedback signal to control system, control system and output to the specified directive metering pump, to open the dosing system to adjust pH value, after being returned to normal pH value, metering pump shut down. If the conductivity is higher than the set value, the system contains excessive salt content, which has the tendency of corrosion. The monitoring instrument will then feed the signal back to the control system, control the system re-export instructions to the blow-down solenoid valve, and the solenoid valve will open the drain, and the solenoid valve will be closed after the electrical conduction is back to normal. Then the metering pump opens up the drug, adds the agent that loses the discharge, maintains the system's drug content in the normal level, adds to the specified time metering pump closes.

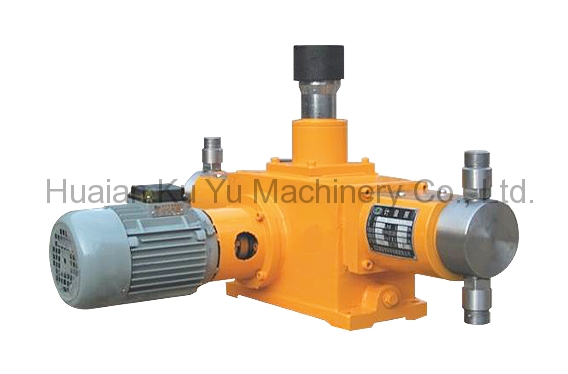

An overview of the metering pump device

Automatic dosing system in electric power, petroleum, chemical industry, metallurgy industry, environmental engineering, water treatment and other fields often needs to be some kind of liquid continuous automatically into another become a kind of mixture in the liquid, or join agents react with some components that exist in the liquid, in order to achieve the desired technical requirements. For best results, in the case of working condition changes, to add chemical medicine dosage automatic tracking adjustment control dosing rate, therefore in the automatic dosing system we have adopted advanced automatic control mode to control the dosage.

The device is simple and easy to install. The automatic additive device is composed of measuring box (dispensing tank), dosage metering pump (adc), automatic control system, connecting pipeline, etc. Automatic dosing system in addition to the part of the dosing pipe line, sampling and dosing concentration measurement instrument, these devices are generally installed between a dosing, automatic dosing system will metering box, metering pump, automatic control system integration, that is installed on a base.

Factory complete equipment purchase, manufacture, assembly, debugging, commissioning, users only need to combined automatic dosing device placed between dosing, dosing pump discharge and dosing piping, metering box import and export and the inlet pipe connection is good, and will power and instrumentation signal to the control cabinet can start and put into operation. This can greatly reduce the construction work, avoids the intermediate link is various of errors and the dispute between each other, effectively guarantee the time limit for a project and the project quality, reduce the user's trouble and loss.

The type and structure of the metering pump device

Dosing pump device mainly has double pump single control modular, three pump double control modular, modular boiler water R value several types, such as automatic control device for each type of structure is somewhat different, the following instructions.

Double pump single control modular automatic dosing device this device consists of a metering box, two sets of dosing pump as spare (), a set of ac frequency conversion type automatic dosing control system, connecting piping, valves, and other components of the base, as shown in figure 1. Metering tank has a capacity of 1 m 'special requirement (the discussion), whether or not to bring a stirring device, remote transmission level gauge, liquid level height limit alarm and material selection by the user or design departments of tank, also can consult my unit directly by the user. The tank body is made of steel, stainless steel and rubber lined with different liquid medicine. When ordering the user, the following parameters of the metering pump must be specified: flow (1 / H), pump outlet pressure (MPa), pump flow material (or the name and concentration of the delivery agent). To control the working process of the drug pump with the sensing signal, the control method is required to use the pH meter, the conductivity meter and other monitoring instruments and corresponding sensors.

First of all, according to the operation need to set control parameters (pH) or conductance value limit value, if the system in the process of running the following dosing system in which to work: if the pH value is less than or greater than set value. The low pH value indicates that the acid is too acidic and the system is prone to corrosion. The pH value is on the high side, indicating the alkaline is too strong, the system has the tendency of scaling. When testing instrument will be the feedback signal to control system, control system and output to the specified directive metering pump, to open the dosing system to adjust pH value, after being returned to normal pH value, metering pump shut down. If the conductivity is higher than the set value, the system contains excessive salt content, which has the tendency of corrosion. The monitoring instrument will then feed the signal back to the control system, control the system re-export instructions to the blow-down solenoid valve, and the solenoid valve will open the drain, and the solenoid valve will be closed after the electrical conduction is back to normal. Then the metering pump opens up the drug, adds the agent that loses the discharge, maintains the system's drug content in the normal level, adds to the specified time metering pump closes.

Ke yu machinery is the factory of huaianga drug metering pump. If you don't know anything about the metering pump, you can call the official website.

Huaian Ku Yu Machinery Co., Ltd.

Address: Fuzhou Road 12, Huaian economic and Technological Development Zone

URL:www.hakyjx.com